The primary technical improvement in recent ten years are the following:

The fourteen “electric welded tube units may be built which could produce tube line welded along with high power and higher deformation, and also the 26” customization electric welded tube units for that production associated with thick walls tube also offers been finished when it comes to improving the actual reliability associated with welding technologies, except with regard to improving the actual high precision from the developed welding manage system, they likewise have developed gasoline shielded welding technologies successfully the actual major breakthrough when it comes to increasing results and reduce costs may be the successful improvement of versatile forming generator (hereinafter known as FF generator), that has been utilized in the manufacturing of little tube. It’s through the perfect control for that contact points from the roll and also the billet to understand the versatile forming, making time of move change as well as adjustment considerably shortened, meanwhile machining deformation brought on by production can also be under manage; laser beam welding will get applied about the production from the alloy pipe and heavy wall tube.

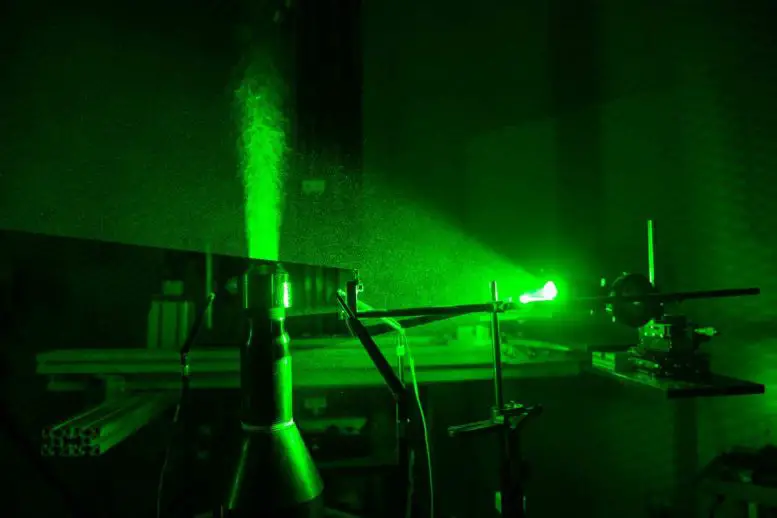

The amalgamated forming tube in auto parts as well as welding pipe production are using higher frequency heating system reducing as well as on-line warmth treatment technologies. With the actual changes associated with main reason for the pipeline, they’ve developed effectively constantly technologies and equipment which could improve effectiveness and ensure the standard. In modern times, due towards the natural gasoline development becomes to remote control areas as well as deep ocean, to conserve pipe investment and also to achieve ruthless and miniaturization, they encourages the UOE tube with higher intensity and incredibly thick walls. For sustaining ultra higher strength, and based on successful improvement of steelmaking technologies and TMCP brand new technology applied within the production associated with heavy dish, the UOE pipe also developed an entire set molding technologies, making the actual X80, X100, X120 along with other products put in continue manufacturing. In the facet of thick walls, to avoid bending whenever laying wreck within the deep ocean, they created the materials and also the welding technology to guarantee the toughness from the weld combined