How can we make battery recycling more cost-effective? The ReCell Center scientists have taken another step towards achieving this goal.

The engines of the technological future and present are lithium-ion batteries. They are powering portable electronics such as smartphones, laptops, and electric vehicles (EVs), and they are increasing in popularity. The technology to recycle lithium-ion batteries has not kept up with the growing use of these batteries, particularly in cars. Scientists at the ReCell Center, the nation’s premier advanced battery recycling research-development center, based at the Department of Energy (DOE) ArgonneNational Laboratory, have made a crucial discovery that eliminates one of the most significant obstacles to making lithium-ion battery recycling economically feasible.

Today’s recycling techniques allow for the recovery of metals in low-value forms. A considerable problem is on the horizon. Researchers project that in less than a decade, two million tons of EV-derived lithium-ion batteries will be retired annually. The current number of EV batteries ending their lives is low but will rise as older vehicles reach the end.

Michigan Technological University (MTU) researchers have created an innovative method to separate the valuable materials that make up a cathode, the positively charged electrode of a battery.

Scientists at the Materials Engineering Research Facility in Argonne are increasing the efficiency of MTU’s separation process and paving the way to large-scale recycling of EV batteries. The cathode materials for EV batteries differ depending on the year and the automaker. A recycler must therefore take a mix of lithium metal oxides, such as lithium cobalt, lithium nickel manganese copper oxide, lithium nickel cobalt aluminum oxide, and lithium iron phosphate. Separate each material to allow them to be reused. This once difficult task suddenly becomes possible.

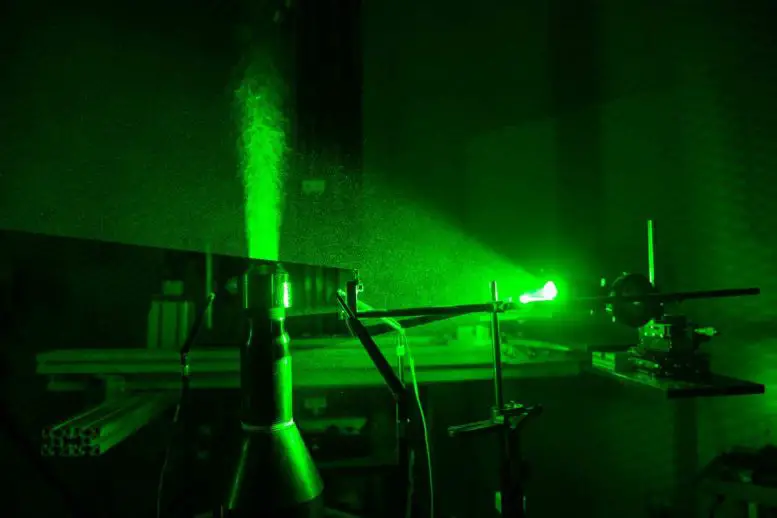

MTU and ReCell scientists have published a paper in the peer-reviewed scientific journal Energy Technology describing their new method for separating individual cathode material using a twist on an older process called “froth flotation.”

Froth flotation has been used in the mining industry for years to separate and purify ore. It is based on whether materials repel water and float or absorb water and sink. Cathode materials tend to sink, which makes it difficult to separate them from one another. This is true for lithium nickel manganese and cobalt oxide (NMC111), two standard EV batteries cathode materials used by the ReCell team in their experiments. The researchers discovered that NMC111, one of the cathode materials, can float by adding a chemical that repels water.

After separating the cathode material, researchers found that it had no effect on the electrochemical performance. Both had high purity levels (95 percent and above).

Jessica Durham, a Materials Scientist at Argonne and coauthor of the study, says this is very important. “They will not sacrifice purity if they buy recycled cathode material for reuse in new batteries.”

This research aligns with the ReCell Center’s mission to develop less energy-intensive processing techniques and capture valuable materials. Direct recycling allows for the immediate recovery, regeneration, and reuse of battery components without breaking down their chemical structure. This center collaborates with Argonne, DOE’s National Renewable Energy Laboratory, Oak Ridge National Laboratory, Michigan Technological University, and Worcester Polytechnic Institute.

ReCell’s breakthrough promises wide-ranging benefits, including a reduction in the cost of recycling lithium-ion batteries; fostering the growth of a profitable recycling market for end-of-life lithium-ion battery batteries; driving down the price of EVs for producers and consumers; enabling America to compete in global battery recycling; strengthening U.S. energy independence through increased domestic use of recycled battery materials; and reducing U.S. dependency on foreign materials.

The ReCell Center team focuses on developing a viable, economically feasible recycling process for lithium-ion batteries. It will only then be widely accepted. “We are putting together the steps knowing that the whole process will have to be profitable in the end.”